16th February 2024

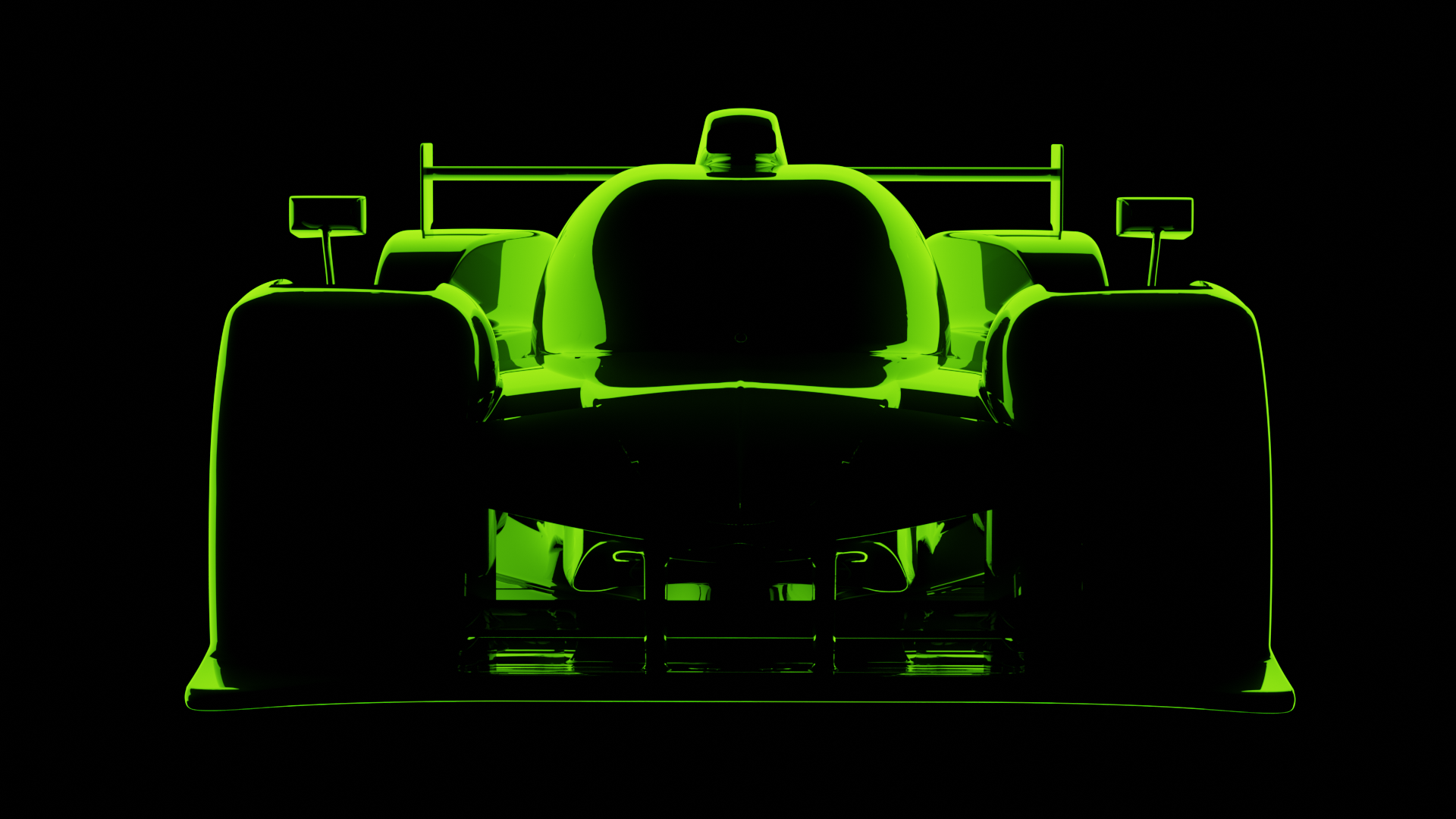

Le Mans Hypercar: designing the new generation of endurance racecars

Starting an ambitious engineering project from a blank sheet of a paper and a design brief is no easy task, but it is one that the team at DEXET Technologies relishes wholeheartedly. With years of experience in high performance composites design, DEXET is all too familiar with projects that may seem unachievable at first. But by applying tried and tested engineering processes and careful project planning, combined with an unshakeable determination to succeed, no challenge is too big for DEXET’s engineering team; and they have proven this countless times over the course of the last few years through a large variety of projects ranging from motorsports to the aerospace industry.

Recently, DEXET’s blank sheet of paper was an empty CAD screen and the design brief was the FIA World Endurance Championship (WEC) 2024 Hypercar regulations, with a customer who wanted to join the highest class of the WEC grid with a brand new entry for this year. They approached the DEXET team looking for help to design the complete composite bodywork of the race car, from conceptualising the aerodynamic surfaces using CFD to engineering the individual panels and detailing the assemblies. The outcome? A fully optimised LMH-class car that meets all of the FIA safety and performance regulations, completed in time to allow the client to carry out a year’s worth of testing prior to the car’s first racing outing.

The key to any successful design project is to ensure that the highest possible level of engineering is achieved in every component, no matter how big or small the part or how tight the deadline. DEXET have developed their own set of design standards from years of experience in high performance engineering, which the team use to normalise their designs across entire projects. These include anything from component interfaces, assembly fixing strategies and component manufacturability to name a few. These standards ensure uniformity across the product and accelerate the design process without compromising the quality of the output. Moreover, they increase the level of traceability in the design process, meaning all clients know to expect a high standard from the very beginning of the project.

For the Hypercar, this translated to details like following set procedures for joining panels together, including pre-defined panel gaps between bodywork components, such that the assembly of the car was significantly simplified. A crucial aspect of designing an endurance race car to compete over 24 hours is the speed at which its components can be replaced during a race, and a simplified assembly facilitates this immensely. The result of applying DEXET’s standards was that, during the car’s very first assembly, all components fit together exactly as designed with no fitment issues, meaning no last-minute design changes were required and strict timelines were maintained.

Another critical side to any project is ensuring there is clear and continuous communication between the design team and the client. This means that any design change that the customer wishes to implement can be captured and adopted quickly into the product, while the client is kept in the loop of all the work DEXET are doing, negating the risk of any surprises arising late in the process.

During the course of the LMH project, DEXET scheduled over 60 hours’ worth of weekly technical debriefs with the client’s project manager and lead engineer – these meetings were used to give a rundown of the work carried out throughout the week, and it gave the client a chance to provide continuous feedback. Moreover, the client was added to DEXET’s internal project communication site, where open discussions were had on a daily basis about design decisions. Because of this, DEXET and the client were both pushing the project in the same direction from day one; anytime an upstream decision was changed, such as the integration of a new electrical component, the rapid communication meant that the design team was always able to turn the modifications around in less than 24 hours to avoid delaying the timelines.

DEXET Technologies cannot wait to see the Hypercar out on track in anger as the team loves to go racing and believes they have done everything they can to deliver a great package. While the racing is undoubtedly exciting, it would never happen without the preparation work that needs to be put in to make it happen, and this is DEXET’s real bread and butter. So if you’re looking to go racing with your product, DEXET is here to help you take your idea to the track. Whether you have a developed idea or are starting from a blank canvas, the team would love to hear from you to discuss how they can use their expertise to help you make the most of it. DEXET is contactable via email at hello@dexet.tech, and face to face meetings at their UK HQ are encouraged.

All images shown in this article are for representation purposes only and are owned by DEXET Technologies Limited.